In the world of cable management, ensuring the safety and longevity of your cables is paramount. One essential aspect of this is sleeving protection. But what exactly is sleeving protection in cables, and why is it crucial? Let's dive into the details.

What Is Sleeving Protection?

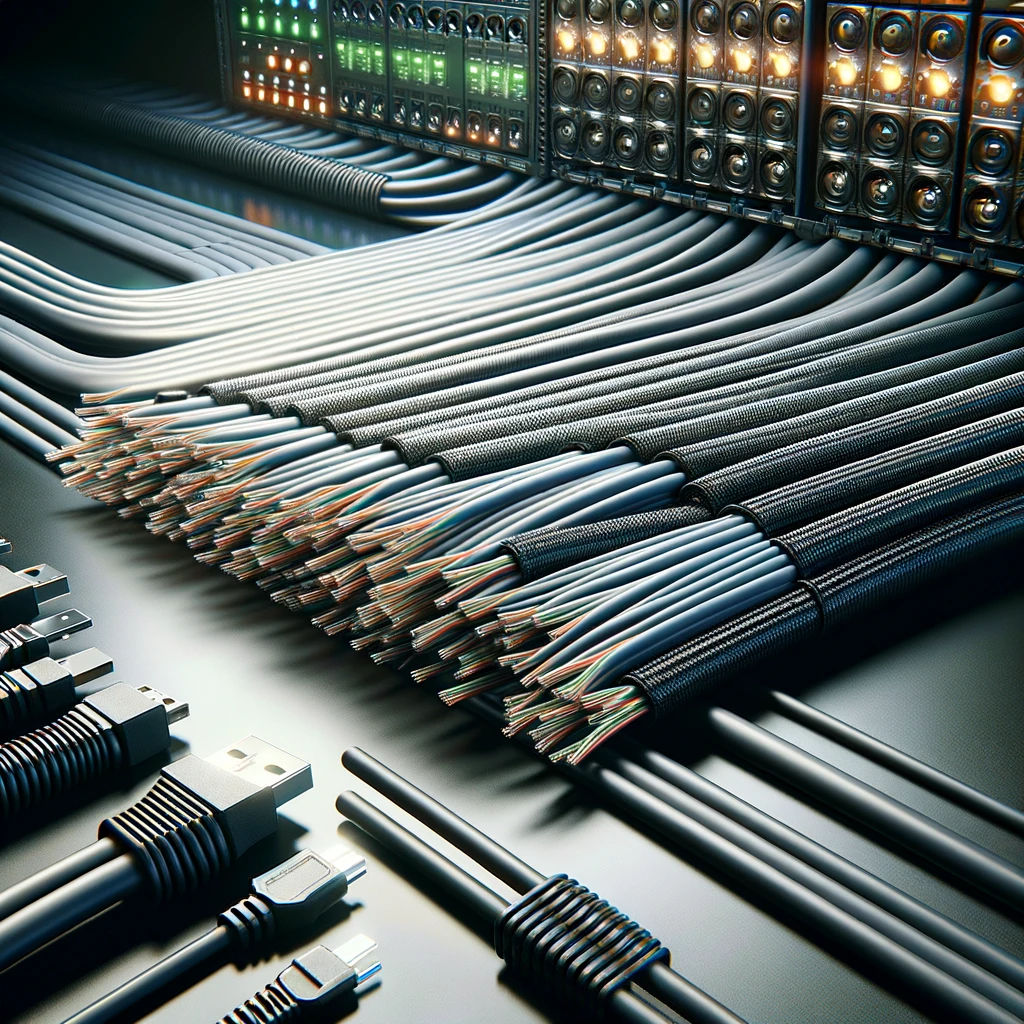

Sleeving protection, also known as cable sleeving, is a flexible material used to cover and protect cables and wires. It comes in various forms, including expandable braided sleeving, heat shrink tubing, and spiral wrap. The primary purpose of sleeving protection is to safeguard cables from abrasion, heat, moisture, and other environmental hazards, prolonging their lifespan and maintaining optimal performance.

Sleeving protection not only shields cables from external elements but also organizes and tidies cable arrangements, reducing clutter and improving aesthetics. This makes it a popular choice in various industries, including electronics, automotive, aerospace, and entertainment, where cable management is critical for safety and efficiency.

Types of Sleeving Protection

1. Expandable Braided Sleeving

This type of sleeving consists of woven polyester or nylon fibers that expand to accommodate cables of different sizes. It offers excellent flexibility and abrasion resistance, making it suitable for a wide range of applications.

2. Heat Shrink Tubing

Heat shrink tubing is a cylindrical sleeve that shrinks in size when heat is applied, conforming tightly to the cables it covers. It provides insulation and protection against moisture, chemicals, and mechanical damage.

3. Spiral Wrap

Spiral wrap is a flexible plastic tubing that wraps around cables in a spiral pattern. It offers easy installation and allows for quick access to individual cables while providing protection against abrasion and tangling.

Importance of Sleeving

Sleeving protection plays a crucial role in safeguarding cables and wires from damage, thereby reducing the risk of electrical malfunctions, fires, and safety hazards. By investing in quality sleeving materials and proper installation, you can ensure the reliability and longevity of your cable infrastructure.

Tips and Tricks for Effective Sleeving Protection

When it comes to sleeving for your cables, a few tips and tricks can make a big difference in ensuring optimal performance and longevity. Here are some expert recommendations to help you get the most out of your sleeving solutions:

1. Choose the Right Material

Selecting the appropriate sleeving material is essential to meet the specific needs of your application. Consider factors such as flexibility, temperature resistance, abrasion resistance, and chemical compatibility when choosing between options like expandable braided sleeving, heat shrink tubing, and spiral wrap.

2. Measure Carefully

Before purchasing sleeving, accurately measure the diameter and length of the cables you intend to cover. This ensures a snug fit and prevents unnecessary waste or insufficient coverage. Remember to account for any connectors or bends in the cable path.

3. Proper Installation

Take the time to install sleeving protection correctly to maximize its effectiveness. Ensure that the sleeving is securely fastened and covers the entire length of the cable, paying attention to entry and exit points. Use heat guns or other appropriate tools to shrink heat shrink tubing evenly and avoid overheating.

4. Bundle Cables Wisely

When bundling cables together with sleeving protection, avoid overcrowding to prevent overheating and signal interference. Maintain adequate spacing between cables and avoid sharp bends or twists that could damage the sleeving or cables.

5. Regular Maintenance

Inspect sleeving regularly for signs of wear, damage, or degradation. Replace any damaged or worn-out sleeving promptly to maintain optimal security. Additionally, periodically check for cable movement or tension that could compromise the integrity of the sleeving.

6. Consider Custom Solutions

In some cases, off-the-shelf sleeving options may not fully meet your requirements. Consider custom sleeving solutions tailored to your specific needs, such as custom colors, sizes, or materials. This ensures the perfect fit and maximum protection for your cables.

Wrapping Up

In conclusion, sleeving protection is an indispensable component of cable management, offering both practical and aesthetic benefits. Whether you're organizing cables in your home entertainment system or securing wiring in an industrial setting, choosing the right sleeving solution can make a significant difference in the performance and lifespan of your cables.