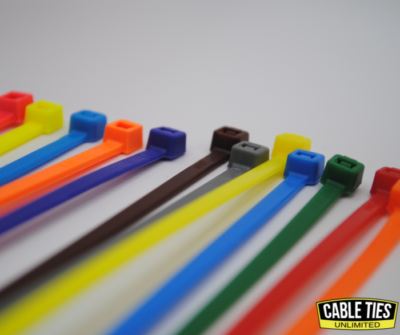

Understanding the concept of cable tie color coding is essential for anyone who uses these versatile tools. Cable ties, those handy fasteners you find in almost every toolkit, serve more purposes than just bundling wires together. They can also communicate valuable information. This practice, known as cable tie color coding, is not just about aesthetics; it plays a crucial role in organization, safety, and efficiency.

The use of different colors in cable ties is a systematic approach to help you identify, categorize, and manage cables easily. Whether you're a professional electrician, a DIY enthusiast, or someone who loves to keep things tidy, grasping the essence of this color-coding system can transform the way you handle your wiring tasks. It's about turning a simple task into an organized strategy.

Significance of Color Coding

The primary purpose of color coding in cable ties is to offer an immediate visual cue. This simplicity is genius. By just glancing, you can determine the purpose, function, or connection type of a bundle of cables. For instance, in some settings, red cable ties might indicate power lines, while green could signify data cables. This method not only saves time but also reduces the risk of errors, especially in complex wiring systems.

Moreover, color coding is invaluable during troubleshooting and maintenance. Imagine diving into a sea of wires and instantly spotting the one you need. It enhances safety too, by clearly marking out different voltages or highlighting critical circuits. The color-coding system acts as a universal language, simplifying communication among team members and ensuring consistency across various projects.

Application Across Industries

Cable tie color coding transcends mere organization; it's a standardized practice in many industries. In the telecommunications sector, specific colors help technicians identify network and connection types swiftly. The automotive industry uses color-coded cable ties to streamline assembly processes and maintenance, ensuring that vital connections are easily and quickly identifiable.

Even beyond industrial applications, color-coded cable ties assist in everyday scenarios. From organizing home entertainment systems to keeping holiday lights untangled, they make life simpler. They're also used in gardening, event management, and even in artistic installations, proving their versatility and utility in countless situations.

Choosing the Right Colors

Selecting the right color for your cable ties involves understanding the common conventions and also the specific requirements of your project or industry. While there's no universal standard, certain colors often have common associations. However, the most important aspect is consistency. Decide on a color scheme and stick to it throughout your project or organization to maintain clarity and efficiency.

Remember, the colors should make sense to you and your team. They should be intuitive, logical, and, most importantly, consistently applied. Whether you're adhering to industry standards or creating a personalized system, the key is uniformity and clear communication.

Tips and Tricks for Effective Cable Tie Color Coding

Mastering the art of cable tie color coding can significantly enhance your cable management, ensuring efficiency, safety, and ease of maintenance. Here are some expert tips and tricks, coupled with best practices, to help you optimize the use of color-coded cable ties in any setting.

Start with a Plan

Before diving into your project, sketch out a color-coding plan. Decide which colors will represent different types of cables, functions, or priorities. This plan will serve as your guide, ensuring consistency and clarity throughout the wiring process. It's crucial that everyone involved understands and follows this scheme to avoid confusion.

Use Standard Colors When Possible

While customization is valuable, adhering to industry-standard colors when they exist can facilitate better understanding and maintenance, especially when multiple people or teams are involved. For example, using red for power lines and green for grounding is common. Standardization promotes uniformity, especially in environments where contractors or new team members might be involved.

Consistency Is Key

Consistency in your color-coding scheme is vital. Once you establish a color code for a particular type of cable or function, stick to it throughout your entire project or facility. This consistency eliminates guesswork, speeds up identification, and can significantly reduce errors during troubleshooting and maintenance.

Labeling Enhances Clarity

Combine your color-coding system with clear, durable labeling. Labels can provide additional information that colors alone might not convey, such as circuit numbers, voltage levels, or destination points. This dual approach reinforces the identification process, making your system even more foolproof.

Regularly Review and Update Your System

Over time, your cable management requirements might evolve due to system upgrades, expansions, or changes in standards. Regularly review your color-coding scheme to ensure it still meets your needs and adjust it as necessary. Keeping your system up-to-date is crucial for ongoing efficiency and safety.

Train Your Team

Ensure that all team members are familiar with the color-coding system. Training should cover not only the meaning of each color but also the importance of adhering to the coding system. A well-informed team is essential for maintaining an organized and safe working environment.

Best Practices for Cable Tie Usage

- Avoid Over-tightening: Ensure that cable ties are secure but not overly tight, as this can damage the cables, especially if they are sensitive data or fiber optic cables.

- Cut Off Excess Tails: Trim the tails of cable ties to prevent snagging, which can lead to accidents or cable damage. Use flush-cutting tools to avoid leaving sharp edges.

- Regular Inspection: Periodically inspect your cable ties and the cables they secure. Look for signs of wear, over-tightening, or environmental damage and replace them as necessary.

- Consider Releasable Ties for Temporary Setups: If your configuration is temporary or likely to change, consider using releasable cable ties. They offer the same organizational benefits but can be easily adjusted or removed as needed.

By integrating these tips, tricks, and best practices into your workflow, you'll create a more organized, efficient, and safer environment for cable management. The effectiveness of cable tie color coding lies in its simplicity and the practical benefits it delivers, making it a cornerstone of good cable management practice.

Wrapping Up

Cable tie color coding is more than just a clever organization hack; it's a pivotal strategy in managing and identifying cables efficiently. By implementing a color-coded system, you enhance safety, streamline troubleshooting, and promote a highly organized working environment. Dive into our latest blog post to explore more innovative ways to leverage the simplicity and effectiveness of cable ties in your projects.

Explore our latest blog post for more insights into innovative cable management solutions and elevate your organizational skills to the next level.