Slotted wall wiring ducts are essential components in cable management systems. They provide an organized and safe way to route, protect, and manage electrical wires in various applications. Their design features evenly spaced slots along the sides, allowing for easy insertion, removal, and organization of wires. These wiring ducts come in adhesive and non-adhesive variants, each catering to specific needs and environments.

In this article, we’ll explore the uses of slotted wall wiring ducts and provide a detailed comparison of adhesive and non-adhesive options to help you make an informed choice.

Uses of Slotted Wall Wiring Duct

Slotted wall wiring ducts are versatile tools for managing cables in various industries and applications. Below are some of their primary uses:

1. Electrical Panel Management

One of the most common uses for slotted wall wiring ducts is in electrical panels. These ducts keep wires neatly organized, reducing clutter and simplifying maintenance.

- Improved Accessibility: Slots allow wires to be routed in and out easily, making adjustments or repairs straightforward.

- Enhanced Safety: By keeping wires securely in place, wiring ducts reduce the risk of electrical hazards such as short circuits or overheating.

- Aesthetic Appeal: Organized wiring creates a professional appearance, which is particularly important in industrial and commercial settings.

2. Data Centers and IT Infrastructure

In environments like data centers, where cable density is high, slotted wall wiring ducts are invaluable. They provide:

- Clear Cable Paths: Prevent tangled cables and maintain proper airflow around sensitive equipment.

- Efficient Organization: Simplify troubleshooting and upgrades by keeping cables well-organized and accessible.

- Cable Protection: Shield cables from external damage, reducing the risk of downtime caused by damaged wires.

3. Industrial Applications

In manufacturing plants and other industrial facilities, wiring ducts play a crucial role in protecting and organizing power and control cables.

- Durability in Harsh Conditions: Many wiring ducts are made from high-quality PVC or other robust materials that can withstand harsh environments.

- Streamlined Maintenance: Properly organized wiring reduces maintenance time and minimizes production downtime.

- Compliance with Standards: Slotted wiring ducts help meet safety and regulatory standards by maintaining orderly and secure cable management.

4. Telecommunications Systems

In telecommunications, where precise cable routing is critical, slotted wiring ducts provide reliable solutions for managing cables in distribution frames and network cabinets.

- Optimized Performance: Proper cable management ensures optimal signal transmission and reduces interference.

- Scalability: Ducts allow for easy expansion and reconfiguration of cable systems as networks grow.

5. Commercial and Residential Applications

Slotted wiring ducts are not limited to industrial or IT environments; they are also used in offices, homes, and retail spaces.

- Office Settings: Organize cables for workstations, conference rooms, and server cabinets.

- Home Use: Neatly manage entertainment systems, home offices, or smart home setups.

- Retail Displays: Keep wiring hidden and organized for point-of-sale systems, digital signage, and lighting systems.

Learn more: High-Density Slotted Wall Wiring Duct: Maximizing Cable Management Efficiency

Adhesive vs. Non-Adhesive Slotted Wall Wiring Ducts

When choosing slotted wall wiring ducts, deciding between adhesive and non-adhesive options is crucial. Both types have distinct advantages and are suited for specific applications.

Adhesive Wiring Ducts

Adhesive wiring ducts feature a pre-applied adhesive backing, allowing for quick and easy installation.

Advantages of Adhesive Wiring Ducts

- Easy Installation:

Adhesive ducts eliminate the need for screws, nails, or other mounting hardware, making installation fast and hassle-free. - Time-Saving:

In scenarios where time is of the essence, adhesive ducts provide a practical solution for quick installations. - Surface-Friendly:

Adhesive ducts are ideal for surfaces where drilling is not feasible or desirable, such as glass, painted walls, or furniture. - Temporary Solutions:

They are an excellent choice for temporary setups, such as trade shows, event venues, or short-term projects. - Cost-Effective for Light Applications:

For light-duty cable management, adhesive ducts provide a budget-friendly option without compromising functionality.

Disadvantages of Adhesive Wiring Ducts

- Limited Durability:

Over time, adhesive backing may lose its strength, especially in environments with high humidity or temperature fluctuations. - Surface Dependency:

Adhesive ducts rely on smooth, clean surfaces for proper adhesion. They may not stick well to rough or uneven surfaces. - Difficult to Reposition:

Once installed, adhesive ducts can be challenging to adjust or remove without damaging the surface or leaving residue. - Weight Limitations:

Adhesive ducts are not suitable for heavy-duty applications or areas with high cable density, as the adhesive may fail under excessive weight.

Non-Adhesive Wiring Ducts

Non-adhesive wiring ducts are mounted using screws, brackets, or other hardware, providing a more permanent and robust solution.

Advantages of Non-Adhesive Wiring Ducts

- High Durability:

Non-adhesive ducts are more secure and can support heavier loads, making them ideal for industrial and high-density applications. - Long-Term Reliability:

Screw-mounted ducts maintain their stability over time, even in challenging environments such as factories or outdoor installations. - Versatility:

These ducts can be installed on virtually any surface, including rough or uneven materials, with the appropriate mounting hardware. - Resistance to Environmental Factors:

Non-adhesive ducts are less affected by temperature changes, humidity, or surface conditions, ensuring consistent performance. - Adjustability:

Unlike adhesive ducts, non-adhesive options allow for easy repositioning or removal without leaving residue or damaging surfaces.

Disadvantages of Non-Adhesive Wiring Ducts

- More Labor-Intensive Installation:

Installing non-adhesive ducts requires additional tools and effort compared to adhesive options. - Longer Installation Time:

The process of drilling holes and securing the ducts with screws can be time-consuming, especially for large-scale projects. - Higher Initial Cost:

The need for mounting hardware and tools increases the upfront cost of installation. - Not Ideal for Temporary Use:

Non-adhesive ducts are better suited for permanent setups and may not be practical for short-term or temporary installations.

Factors to Consider When Choosing Between Adhesive and Non-Adhesive Wiring Ducts

To decide which type of slotted wiring duct is best for your needs, consider the following factors:

1. Application Requirements

- For light-duty, indoor, or temporary setups, adhesive ducts are a convenient choice.

- For heavy-duty, outdoor, or industrial applications, non-adhesive ducts offer better durability and security.

2. Surface Type

- Smooth, clean surfaces are ideal for adhesive ducts.

- Rough or uneven surfaces may require non-adhesive ducts with screw mounting.

3. Cable Load

- Adhesive ducts are suitable for low to moderate cable density.

- High cable density or heavy loads necessitate the use of non-adhesive ducts.

4. Environmental Conditions

- In environments with high humidity, extreme temperatures, or exposure to chemicals, non-adhesive ducts are more reliable.

- Adhesive ducts perform best in controlled indoor settings.

5. Budget and Time Constraints

- Adhesive ducts save time and are cost-effective for smaller projects.

- Non-adhesive ducts require more time and investment but offer superior long-term reliability.

Learn more about our other wiring solutions: F6 Woven Braided Sleeving: A Flexible Solution for Cable Management

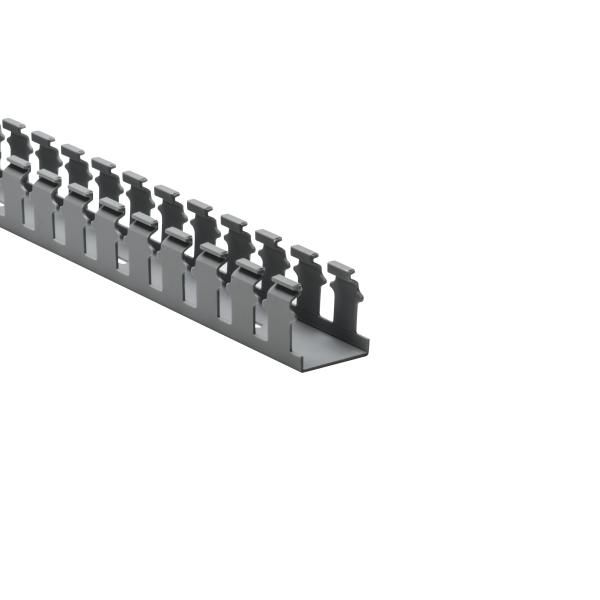

Product Review: HellermannTyton 181-21004 Slotted Wall Wiring Duct

The HellermannTyton 181-21004 Slotted Wall Wiring Duct is a durable, non-adhesive cable management solution ideal for industrial and professional use. Its strong PVC construction ensures long-term reliability, while self-extinguishing properties add safety in electrical setups.

Key features include robust fingers that resist breaking, secure slots that prevent unintended wire removal, and compatibility with screws or brackets for stable mounting. The sleek gray design improves aesthetics in panels or cabinets, and compliance with UL and ROHS standards ensures performance and safety.

This duct is perfect for electrical panels, data centers, and control cabinets, offering neat organization and easy maintenance. While it requires more effort to install compared to adhesive ducts, the result is a secure and professional-grade solution. For long-lasting and dependable cable management, the HellermannTyton 181-21004 is a top choice.

Wrapping Up

Slotted wall wiring ducts are versatile tools for cable management, with applications ranging from electrical panels and data centers to home offices and industrial facilities. Choosing between adhesive and non-adhesive options depends on your specific needs, environment, and the scale of your project.

Adhesive wiring ducts are ideal for quick, temporary, or light-duty installations on smooth surfaces. In contrast, non-adhesive wiring ducts provide the durability and reliability needed for heavy-duty, permanent setups in challenging environments.

For more insights and tips on cable ties and other related products, explore cabletiesunlimited.com and follow us on our social media communities on Facebook and Instagram!