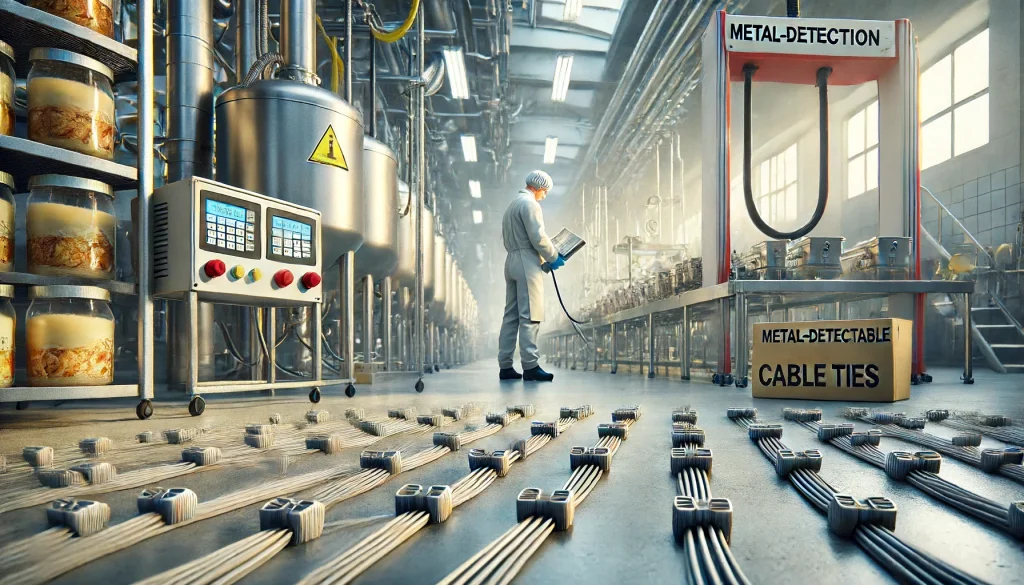

Ensuring the safety and quality of food products is a top priority for food processing plants. One of the most effective ways to mitigate the risk of contamination is by using metal-detectable cable ties. These specialized cable ties are designed to be easily detected by metal detectors and X-ray machines, ensuring that no foreign objects end up in the final product.

Metal-detectable cable ties play a crucial role in maintaining food safety standards. In this article, we will explore how to effectively use these cable ties to minimize contamination risks in food processing plants. We will cover their benefits, applications, and best practices to ensure optimal safety and compliance.

The Importance of Metal-Detectable Cable Ties

In food processing plants, contamination can lead to severe consequences, including product recalls, financial losses, and damage to a company's reputation. Metal-detectable cable ties serve as essential tools that actively prevent such incidents.

By using metal-detectable cable ties, food production processes significantly enhance overall safety. These ties, designed for easy detection by standard detection systems, reduce the risk of undetected contamination and ensure that the final product is safe for consumption.

How Metal-Detectable Cable Ties Work

Manufacturers make metal-detectable cable ties from a combination of nylon and metal particles. This unique composition maintains the strength and flexibility of traditional nylon ties while making them detectable by metal detectors and X-ray machines. Their dual functionality makes them ideal for use in environments where food safety is paramount.

When a metal-detectable cable tie or fragment passes through a detection system, the embedded metal particles trigger an alarm. This detection ensures that workers identify and remove any foreign objects before they can contaminate the food products. This simple yet effective mechanism plays a crucial role in maintaining the integrity of the food production process.

Benefits of Using Metal Detectable Cable Ties

Using metal-detectable cable ties offers several benefits beyond contamination prevention. These ties enhance overall operational efficiency, ensure regulatory compliance, and contribute to a safer work environment. Let's explore these benefits in detail.

Enhanced Safety and Compliance

Metal-detectable cable ties help food processing plants comply with strict safety regulations. Regulatory bodies, such as the FDA and HACCP, have stringent guidelines to ensure food safety. Using detectable cable ties demonstrates a commitment to these standards, helping plants avoid costly fines and recalls.

Operational Efficiency

These cable ties also improve operational efficiency. By preventing contamination, they reduce the risk of production line shutdowns and product recalls. This leads to smoother operations, fewer disruptions, and ultimately, cost savings for the business.

Versatility

Metal detectable cable ties are versatile and can be used in various applications within the food processing plant. From bundling cables to securing equipment, their flexibility and strength make them suitable for multiple uses, enhancing the overall efficiency of the production process.

Applications of Metal Detectable Cable Ties

Metal-detectable cable ties can be used in a variety of applications within food processing plants. Their primary purpose is to prevent contamination, but they also offer additional benefits in terms of organization and safety. Let's explore some common applications.

Securing Cables and Wires

In food processing plants, workers use cables and wires to power equipment and systems. Loose or unorganized cables can pose a safety risk and hinder operations. To address this, workers employ metal-detectable cable ties to bundle and secure these cables, ensuring they are neatly organized and do not interfere with the production process.

Bundling Equipment and Tools

Loose equipment and tools can also be a source of contamination. Using metal-detectable cable ties to bundle and secure these items helps keep the work area tidy and reduces the risk of items falling into the production line. This not only enhances safety but also improves efficiency by keeping everything in its place.

Securing Bags and Packaging

Metal-detectable cable ties also prove useful for securing bags and packaging in food processing plants. Bags containing ingredients or finished products require secure closures to prevent contamination. These cable ties offer a secure seal that can be easily detected if accidentally cut or lost, ensuring that no fragments contaminate the product.

Best Practices for Using Metal Detectable Cable Ties

To get the most out of metal-detectable cable ties, it's important to follow best practices. Proper use and regular maintenance can ensure that these ties perform effectively and contribute to a safer production environment. Here are some key best practices to consider.

Regular Testing and Inspection

Regular testing and inspection of metal-detectable cable ties are crucial. Ensure that the ties are easily detectable by the plant's detection systems. Conduct routine tests by running sample ties through metal detectors and X-ray machines to verify their detectability.

Proper Installation

Proper installation of metal-detectable cable ties is essential. Avoid over-tightening the ties, as this can cause them to break or become difficult to remove. Ensure that the ties are securely fastened but not so tight that they damage the cables or equipment they are securing.

Routine Maintenance

Regularly maintaining cable ties and detection systems is crucial for ensuring ongoing safety. Inspect the ties routinely for signs of wear and tear, and replace any that are damaged. Additionally, check the detection systems regularly to ensure they function correctly and calibrate them routinely.

Choosing the Right Metal Detectable Cable Ties

Selecting the appropriate metal-detectable cable ties for your food processing plant involves considering several factors, including material, size, and tensile strength. Choosing the right ties ensures optimal performance and safety.

Material

Most metal-detectable cable ties are nylon with embedded metal particles. However, some applications may require ties made from different materials, such as heat-resistant or UV-resistant nylon. Choose the material that best suits the specific needs of your plant.

Size and Tensile Strength

The size and tensile strength of the cable ties should match the application. For bundling small cables, smaller ties with lower tensile strength may be sufficient. For securing heavy equipment, opt for larger ties with higher tensile strength to ensure a secure hold.

Detection Capabilities

Ensure that the metal-detectable cable ties you choose are compatible with your plant's detection systems. Test the ties to verify their detectability and ensure they meet the required standards for food safety.

Common Mistakes to Avoid

When using metal-detectable cable ties, it's important to avoid common mistakes that can compromise their effectiveness. Being aware of these pitfalls can help you use the ties more effectively and maintain a safe production environment.

Over-Tightening

One common mistake is over-tightening the cable ties. This can cause the ties to break or become difficult to remove. It can also damage the cables or equipment they are securing. Ensure that the ties are tightened just enough to hold the items securely without causing damage.

Neglecting Regular Inspections

Neglecting regular inspections can lead to undetected wear and tear on the cable ties. Regularly inspect the ties for signs of damage and replace any that show signs of wear. This helps maintain the integrity of the production process and prevents contamination.

Conclusion

Metal-detectable cable ties are essential tools for mitigating the risk of contamination in food processing plants. By using these ties, plants can enhance safety, ensure compliance with regulations, and improve operational efficiency. Proper use, regular testing, and routine maintenance are key to maximizing the benefits of metal-detectable cable ties.

For more insights and tips on cable ties and other related products, be sure to explore cabletiesunlimited.com and follow us on our social media communities on Facebook and Instagram!

Want to speak with one of our professionals? Reach out at 866-891-0137 and we'll be delighted to help!