Everything You Need to Know About Stainless Steel Ladder Cable Ties

Ladder cable ties provide a versatile and efficient solution for organizing cables and wires in various settings. From home organization to industrial applications, these cable ties offer reliable support and secure fastening, ensuring neat and tidy cables.

This in-depth review guides you through the advantages and features of different stainless steel ladder cable ties, helping you make an informed choice based on your project's specific requirements.

Are you tired of messy cables and wires cluttering your workspace? Cable management is crucial for maintaining a clean and organized environment, and stainless steel ladder ties are here to help. In this article, we will explore the benefits, applications, features, and tips for choosing and using stainless steel ladder ties.

Whether you are an electrician, HVAC technician, or involved in construction projects, these versatile ties are a game-changer. Let's dive in and discover how Cable Ties Unlimited can provide you with the perfect solution for your cable management needs.

Applications of Stainless Steel Ladder Ties

Stainless steel ladder ties have a wide range of applications in various industries and projects. Their durability, strength, and resistance to corrosion make them an ideal choice for securing and organizing cables and wires. Let's explore some of the key applications where stainless steel ladder ties excel:

Use in Industrial Settings

In industrial settings, where heavy machinery and equipment are in operation, cable management is crucial for safety and efficiency. Stainless steel ladder ties provide a secure and reliable solution for bundling and securing cables in these demanding environments. Whether it's in manufacturing plants, warehouses, or industrial facilities, these ties ensure that cables are neatly organized and protected from damage.

Industrial professionals, such as maintenance technicians and machine operators, rely on stainless steel ladder ties to keep their work areas safe and free from cable hazards. The robust construction of these ties ensures that they can withstand the rigors of industrial environments, including exposure to chemicals, extreme temperatures, and vibrations.

Use in Construction Projects

In the construction industry, where multiple trades are working simultaneously, cable management is essential to maintain a smooth workflow and prevent accidents. Stainless steel ladder ties are widely used in construction projects to secure and organize cables in buildings, bridges, tunnels, and other structures.

From electrical wiring to data cables and plumbing lines, these ties provide a reliable solution for keeping cables in place and preventing tangling or tripping hazards. Construction professionals, including electricians, plumbers, and HVAC technicians, appreciate the durability and versatility of stainless steel ladder ties, as they can be easily adjusted and reused as needed during the construction process.

Use in Electrical Installations

Electrical installations require precise cable management to ensure the safety and efficiency of the electrical systems. Stainless steel ladder ties are commonly used by electricians and electrical contractors to secure and organize cables in residential, commercial, and industrial buildings.

These ties offer a secure and long-lasting solution for bundling and routing electrical cables, whether it's for power distribution, lighting systems, or communication networks. The high tensile strength of stainless steel ladder ties ensures that cables are held securely in place, even in high-vibration environments.

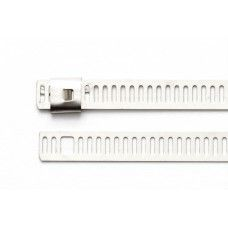

Features and Specifications of Stainless Steel Ladder Ties

Stainless steel ladder ties are known for their exceptional features and specifications that set them apart from other cable management solutions. Let's take a closer look at what makes these ties a top choice for professionals:

Material Composition and Durability

Stainless steel ladder ties are made from high-quality stainless steel, which offers excellent durability and strength. The stainless steel material ensures that these ties can withstand heavy loads and provide long-lasting performance in various environments.

Compared to plastic or nylon cable ties, stainless steel ladder ties offer superior resistance to wear and tear, making them suitable for demanding applications. Whether you're working in extreme temperatures, high humidity, or corrosive environments, these ties will maintain their integrity and keep your cables securely in place.

Additionally, the stainless steel construction provides excellent resistance to UV radiation, ensuring that the ties won't degrade or become brittle when exposed to sunlight. This makes them a reliable choice for both indoor and outdoor cable management needs.

Size and Length Options

Stainless steel ladder ties come in a variety of sizes and lengths to accommodate different cable management requirements. Whether you need to secure a few small cables or bundle larger bundles, there's a size and length option available to suit your needs.

Typically, stainless steel ladder ties range from 4 inches to 36 inches in length, allowing for flexibility in securing cables of various sizes. The width of the ties can vary as well, with options ranging from 0.18 inches to 0.35 inches, providing the necessary strength and stability for different cable management applications.

When selecting the right size and length of ladder ties, consider the diameter and quantity of cables you need to secure. It's important to choose ties that can comfortably accommodate your cables without being too loose or too tight.

Resistance to Corrosion and Extreme Conditions

One of the standout features of stainless steel ladder ties is their exceptional resistance to corrosion and extreme conditions. The stainless steel material is inherently resistant to rust and oxidation, making these ties suitable for use in harsh environments.

Whether you're working in marine settings, chemical plants, or outdoor installations, stainless steel ladder ties will maintain their integrity and performance. They can withstand exposure to moisture, chemicals, and other corrosive substances without deteriorating or compromising the security of your cables.

Furthermore, stainless steel ladder ties are designed to withstand extreme temperatures, both hot and cold. They won't become brittle or lose their strength when exposed to freezing temperatures or high heat, ensuring reliable cable management in any climate.

Professionals Who Rely on Stainless Steel Ladder Ties

Stainless steel ladder ties are a staple tool for professionals in various industries who require secure and organized cable management solutions. Let's explore the specific professionals who rely on these durable and versatile ties:

Electricians and Electrical Contractors

Electricians and electrical contractors heavily depend on stainless steel ladder ties to manage their cables. Whether tackling residential, commercial, or industrial installations, these ties deliver a secure, efficient method for bundling and organizing cables.

Electricians value the ladder ties' strength and durability, ensuring cables remain secure and undamaged. High tensile strength allows these ties to hold cables firmly, even in environments with high vibration.

Additionally, the corrosion resistance of stainless steel ladder ties makes them ideal for both indoor and outdoor electrical projects. Electricians can rely on these ties to sustain their performance and integrity, even in demanding conditions.

Telecommunication and Network Technicians

Telecommunication and network technicians rely on stainless steel ladder ties to manage the complex web of cables and wires in their installations. From data centers to telecommunications infrastructure, these professionals require a secure and organized solution for bundling and routing cables.

Stainless steel ladder ties offer the strength and durability needed to secure and organize the numerous cables found in telecommunication and network systems.

Furthermore, the resistance to corrosion and extreme conditions makes stainless steel ladder ties suitable for both indoor and outdoor telecommunication and network installations. Technicians can trust that these ties will withstand the demands of their work environments and provide long-lasting cable management solutions.

Tips for Choosing and Using Stainless Steel Ladder Ties

When it comes to choosing the right stainless steel ladder ties for your cable management needs, there are several factors to consider. From selecting the appropriate size and length to ensuring proper installation techniques, these tips will help you make the most out of your ladder ties:

Factors to Consider When Selecting Ladder Ties

1. Strength and Durability

Look for ladder ties that are made from high-quality stainless steel to ensure they can withstand the weight and tension of your cables. Consider the maximum load capacity of the ties and choose accordingly.

2. Size and Length

Determine the diameter and quantity of cables you need to secure, and select ladder ties that can comfortably accommodate them. Choose the appropriate length to ensure a secure and snug fit without excess tie material.

3. Resistance to Corrosion

If you're working in environments with high humidity, exposure to chemicals, or outdoor installations, opt for ladder ties with excellent corrosion resistance. Stainless steel ladder ties are known for their resistance to rust and oxidation, making them a reliable choice.

4. UV Resistance

If you're planning to use ladder ties in outdoor applications, consider their resistance to UV radiation. Look for ties that won't degrade or become brittle when exposed to sunlight, ensuring long-lasting performance.

5. Reusability

If you anticipate the need to adjust or reuse your ladder ties, choose ones that are designed for easy release and reusability. This will save you time and money in the long run.

Proper Installation Techniques

1. Prepare the Cables

Before securing the cables with ladder ties, ensure they are free from tangles. This will make the installation process smoother and prevent any damage to the cables.

2. Choose the Right Tightness

When tightening the ladder ties, avoid overtightening, as this can damage the cables or restrict their movement. On the other hand, ensure the ties are tight enough to hold the cables securely in place without any slippage.

3. Trim Excess Tie Material

After securing the cables, trim any excess tie material to maintain a neat and professional appearance. Use appropriate tools, such as cable tie cutters, to ensure clean and precise cuts.

4. Consider Cable Accessibility

When installing ladder ties, consider the accessibility of the cables in case you need to make changes or additions in the future. Leave enough space and avoid over-securing the cables to allow for easy access when needed.

Maintenance and Care Tips

1. Regular Inspections

Periodically inspect your ladder ties to ensure they are still securely holding the cables in place. Check for any signs of wear, damage, or corrosion, and replace any ties that show signs of deterioration.

2. Keep Cables Organized

As your cable management needs evolve, make sure to reorganize and adjust the ladder ties accordingly. This will help maintain a clean and organized workspace and prevent any potential hazards.

3. Protect from Extreme Conditions

While stainless steel ladder ties are designed to withstand extreme conditions, it's still important to protect them from unnecessary exposure to harsh environments whenever possible. This will help prolong their lifespan and ensure optimal performance.

Product Comparison: A Deep Dive into Stainless Steel Ladder Cable Ties

Analyzing Material and Design

When looking at the 316 Stainless Steel Ladder Cable Ties, the first thing to note is their self-locking design, which offers quick and secure installation. Made from 316 stainless steel, this product is ideal for applications requiring resistance to corrosion, vibration, radiation, and extreme temperatures. These cable ties also stand out for their fireproof, UV resistant, and halogen-free properties.

Comparing Functionality Across Lengths and Coatings

Now let's get into the length variations. The first product offers lengths ranging from 7 to 17 inches, each with a tensile strength of 150 pounds. That's a wide range of options to suit different project requirements. The 7" 150lb Black Polyester Coated 316 Stainless Steel Ladder Cable Ties differ slightly in that they feature a pure polyester coating, but keep the core 316 stainless steel.

Wrapping Up

Choosing the right stainless steel cable ties depends on your specific needs, be it length, tensile strength, or specialized coatings. Each of the three products we reviewed offers something unique, whether it's a wide range of lengths, a polyester coating for added protection, or a middle-of-the-road 10-inch option. Assess your project requirements carefully to make the best choice.

Learn about our other products: Versatility and Convenience of Double Loop Cable Ties