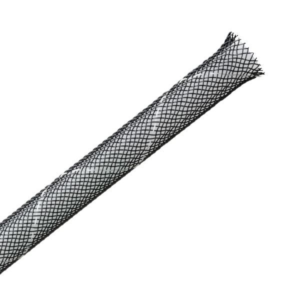

Braided cable sleeving is a protective covering used to encase and shield cables, wires, and hoses. This sleeving is typically made from flexible materials like polyester or nylon and features a woven or braided design that allows for easy installation and removal. Braided cable sleeving serves multiple purposes, including cable organization, protection against abrasion, and electromagnetic interference (EMI) shielding.

One of the key advantages of braided cable sleeving is its ability to protect cables and wires from physical damage, such as abrasion and wear caused by friction. It also provides insulation against heat and can effectively contain and bundle multiple cables, keeping them organized and preventing tangling. In addition, some braided sleeving is designed to offer EMI shielding, reducing electromagnetic interference that can affect electronic equipment.

The operation of braided cable sleeving involves sliding it over the cables or wires to be protected and securing the ends as needed. This flexible and versatile solution is commonly used in various industries, including electronics, automotive, and telecommunications, where cable protection and organization are essential. Braided cable sleeving is available in different sizes, colors, and materials to accommodate specific needs and preferences.

Also see: Polyolefin Heat Shrink Tubing