Colored Heat Shrink Tubing: Versatile Solution for Insulation and Identification

Heat shrink tubing is a versatile and essential component in various electrical and mechanical applications. But have you considered the benefits of using colored heat shrink tubing? In this blog post, we'll explore the many advantages and uses of colored heat shrink tubing and how it can enhance your projects.

Heat shrink tubing is a versatile and essential component in various electrical and mechanical applications. It provides insulation, protection, and strain relief for wires, cables, and connectors. But have you considered the benefits of using colored shrink tubing? In this blog post, we'll explore the many advantages and uses of colored shrink tubing and how it can enhance your projects.

What is Heat Shrink Tubing?

Before we dive into the benefits of colored heat shrink tubing, let's briefly discuss what heat shrink tubing is. Heat shrink tubing is a flexible, cylindrical tubing made from thermoplastic materials. When exposed to heat, it shrinks and conforms tightly to the shape of the object it's applied to, creating a snug and protective covering.

Advantages of Colored Heat Shrink Tubing

Colored shrink tubing offers several advantages over traditional clear or black tubing. Here are some key benefits:

- Easy Identification: Colored shrink tubing allows for quick and easy identification of wires, cables, and components. By assigning different colors to various functions or categories, you can easily distinguish between them at a glance. This is particularly useful in complex wiring systems or when troubleshooting.

- Color-Coding: Color-coding your wires and cables using heat shrink tubing helps maintain organization and consistency. You can establish a color scheme that follows industry standards or create your own custom coding system. For example, red for power, black for ground, and yellow for data. Color-coding reduces errors and saves time during installation and maintenance.

- Enhanced Aesthetics: Colored heat shrink tubing adds a professional and polished look to your projects. It can conceal unsightly wires and connections while providing a clean and organized appearance. Whether you're working on a car audio system, a robotics project, or a custom electronic device, colored heat shrink tubing can elevate the visual appeal.

- Insulation and Protection: Like clear or black heat shrink tubing, colored tubing provides excellent insulation and protection for wires and connections. It shields against abrasion, moisture, and extreme temperatures, preventing short circuits and ensuring the longevity of your electrical components.

- Strain Relief: Heat shrink tubing offers strain relief for wires and cables, especially at connection points. It absorbs stress and prevents damage caused by pulling, bending, or vibration. Colored heat shrink tubing performs this function while adding the benefit of easy identification.

Applications of Colored Heat Shrink Tubing

Colored heat shrink tubing finds applications across various industries and projects. Here are some common uses:

- Automotive Wiring: In automotive electrical systems, colored shrink tubing is widely used to organize and identify wires. It helps technicians quickly locate specific wires during repairs or modifications, saving time and reducing the risk of errors.

- Electronics: Colored heat shrink tubing is a staple in electronic projects, from DIY hobbyist builds to professional installations. It provides insulation, protection, and identification for wires, components, and connections. It's particularly useful in projects involving multiple sensors, actuators, or communication lines.

- Audio/Video Systems: In audio and video installations, colored shrink tubing helps keep wires organized and easily identifiable. It's commonly used in home theater setups, recording studios, and live sound systems to manage the numerous cables involved.

- Robotics and Automation: Robotics and automation projects often involve complex wiring and connections. Colored heat shrink tubing allows for clear identification of power, data, and control lines, making troubleshooting and maintenance more efficient.

- Aerospace and Military: In aerospace and military applications, where reliability and precision are critical, colored heat shrink tubing is used to identify and protect wires and cables. It ensures proper connections and helps technicians quickly identify and replace damaged or faulty components.

How to Apply Colored Heat Shrink Tubing

Applying colored heat shrink tubing is a straightforward process. Here are the basic steps:

- Measure and Cut: Measure the length of heat shrink tubing needed to cover the desired area, considering the shrinkage ratio. Cut the tubing to size using scissors or a tubing cutter.

- Slide Over the Wire: Slide the cut piece of heat shrink tubing over the wire or connection you want to protect. Ensure that it covers the area completely.

- Apply Heat: Using a heat gun, lighter, or other heat source, apply even heat to the tubing. Start from the center and work your way towards the ends. The tubing will shrink and conform tightly to the wire or connection.

- Cool and Inspect: Allow the heat shrink tubing to cool completely. Inspect the coverage to ensure it has shrunk properly and provides adequate protection.

Choosing the Right Colored Shrink Tubing

When selecting colored shrink tubing for your projects, consider the following factors:

- Material: Heat shrink tubing is available in various materials, such as polyolefin, PVC, and fluoropolymers. Choose a material that suits your application's requirements for temperature resistance, chemical resistance, and flexibility.

- Shrinkage Ratio: Heat shrink tubing comes in different shrinkage ratios, typically ranging from 2:1 to 6:1. The shrinkage ratio indicates how much the tubing will shrink when heated. Consider the size of your wires or components and choose a ratio that provides a snug fit.

- Color Options: Heat shrink tubing is available in a wide range of colors. Select colors that align with your identification or color-coding needs. Some common colors include red, blue, yellow, green, and black.

- Durability: Consider the durability requirements of your application. Some heat shrink tubing is designed for harsh environments, offering resistance to abrasion, chemicals, and extreme temperatures. Choose a tubing that can withstand the conditions your project will face.

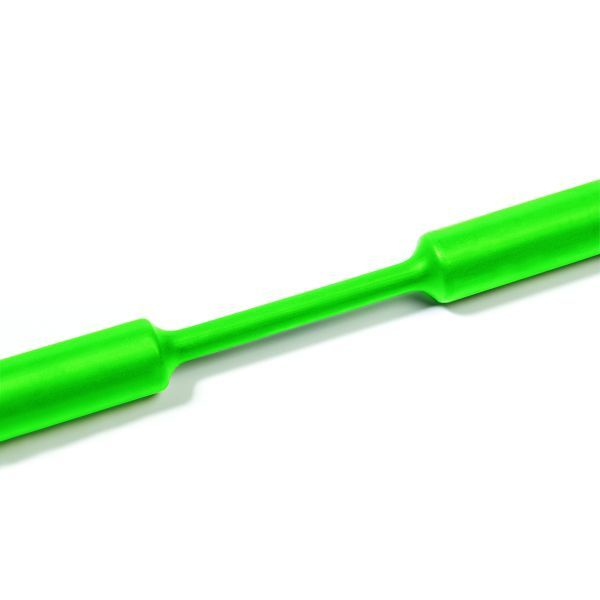

Product Highlight: HellermannTyton 309-60284 Heat Shrink Tubing

Efficient Wire Protection: The HellermannTyton 309-60284 Heat Shrink Tubing offers efficient insulation and abrasion protection for wires and cables. With a thin, 2:1 shrink ratio design, it ensures snug fitting and reliable performance in various applications.

High Flame Protection: Featuring a UL 224 VW-1 flammability rating, this heat shrink tubing provides the highest degree of flame protection, making it suitable for applications requiring stringent safety measures. Its green color option further enhances visibility and identification in cable management.

Resilient Material: Crafted from Polyolefin, cross-linked (PO-X), this tubing exhibits flexibility and durability, resisting common oils, chemicals, and fluids. This resilience ensures longevity and reliability in challenging environments, enhancing the lifespan of wire and cable installations.

Wide Range of Applications: Available in a variety of diameters and colors, the 309-60284 Heat Shrink Tubing offers versatility for identifying and marking wires and cables. Whether in electrical, automotive, or industrial settings, it provides a solution for diverse cable management needs.

Convenient Packaging Options: Available in mini reels, bulk reels, and sticks, this heat shrink tubing caters to small to large volume applications. Its convenient packaging options facilitate efficient usage and storage, catering to different project requirements.

Also see: Heat Shrink Guns: A Versatile Tool for Cable Tie Users

Conclusion

Colored shrink tubing is a versatile and valuable tool for anyone working with wires, cables, and electrical components. It offers the benefits of easy identification, color-coding, insulation, protection, and strain relief, all while enhancing the aesthetics of your projects.

By choosing the right colored shrink tubing and applying it correctly, you can streamline your work, reduce errors, and ensure the longevity and reliability of your electrical systems. Whether you're a professional technician or a DIY enthusiast, incorporating colored heat shrink tubing into your projects can make a significant difference.

For more insights and tips on cable ties and other related products, be sure to explore cabletiesunlimited.com and follow us on our social media communities on Facebook and Instagram!

Want to speak with one of our professionals? Reach out at 866-891-0137 and we'll be delighted to help!