Cable ties are essential for organizing and securing wires, cables, and other objects in various settings. However, installing zip ties in tight spaces can be challenging, requiring specific techniques and tools to achieve a neat and secure result.

In this blog post, we'll explore some effective methods for installing zip ties in confined areas, ensuring that your cables remain tidy and well-managed even in the most challenging spaces.

Choosing the Right Zip Ties

When working in tight areas, selecting the appropriate cable ties is crucial. Opt for thin, flexible zip ties that can easily navigate through narrow spaces. Consider using miniature or low-profile zip ties specifically designed for confined applications.

These smaller zip ties offer the same strength and durability as their larger counterparts while allowing for easier installation in tight spots. They are perfect for securing wires in electronics, automotive systems, and other space-constrained environments.

Using Cable Tie Installation Tools

Investing in specialized cable tie installation tools can greatly simplify the process of securing ties in tight areas. These tools, such as cable tie guns or tensioning tools, allow for precise control and tension adjustment, ensuring a snug and secure fit.

Cable tie guns feature elongated nozzles that can reach into narrow spaces, making it easier to position and tighten the tie without struggling. They also provide consistent tension, preventing over-tightening that could damage delicate wires or components.

Implementing the Loop Method

The loop method is a handy technique for installing zip ties in tight areas. Begin by creating a loop with the cable tie, passing the tail end through the head to form a loose circle. Insert the loop around the cables or objects you wish to secure.

Next, use a pair of needle-nose pliers or tweezers to grasp the tail end of the tie and pull it tight. This method allows you to position the tie accurately and tighten it without needing excessive space for maneuvering.

Utilizing Tweezers and Hemostats

When working in extremely tight spaces, tweezers and hemostats can be your best friends. These slender, precise tools enable you to grip and manipulate zip ties in areas where fingers alone cannot reach.

Hemostats, in particular, are invaluable for cable tie installation. Their locking mechanism allows you to clamp down on the tie and maintain a secure grip while you position and tighten it. This level of control is especially useful when dealing with delicate wires or components.

Planning Cable Routing

Before installing zip ties, plan your cable routing strategically. Identify the most efficient path, considering obstacles or tight spaces. By mapping your route, you can minimize challenging installations.

Whenever possible, route cables through accessible spaces like cable trays or conduits. This reduces the number of ties required in tight spots. When cables must pass through confined areas, use cable tie mounts or adhesive bases. These provide anchor points for the ties, making installation easier and more secure. Proper planning ensures a tidy and reliable cable setup.

Automotive Industry

Securing Vehicle Wiring Systems

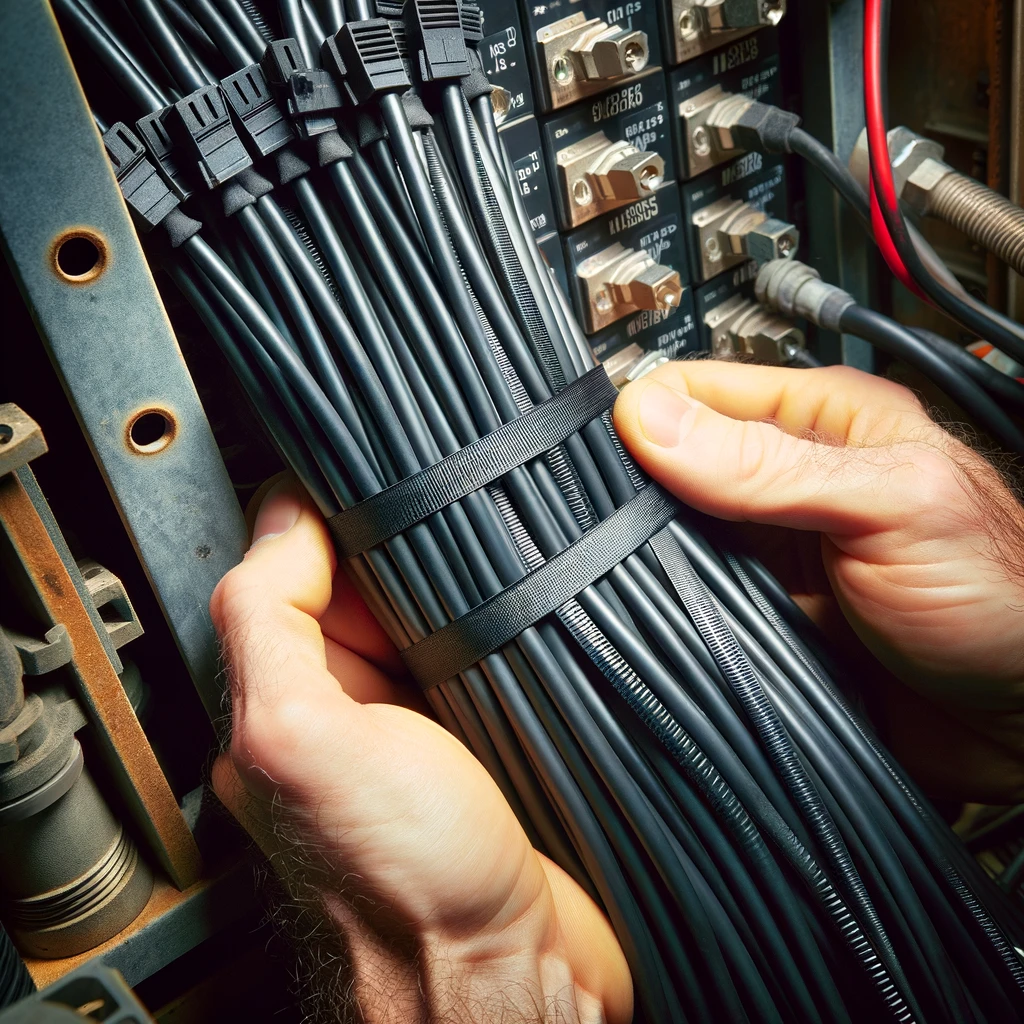

Installing cable ties in tight areas is essential in the automotive industry. Vehicles have complex electrical networks with many wires running through tight spaces.

These spaces include door frames, under the dashboard, and within the engine compartment. By using proper methods, technicians can secure and organize wires efficiently.

Properly installed zip ties prevent wires from chafing against sharp edges. This reduces the risk of electrical shorts and improves the wiring harness's durability. Ensuring a clean and reliable electrical system is crucial for vehicle safety and performance.

Enhancing Vehicle Performance and Reliability

Properly installing zip ties in tight areas of vehicles enhances performance, reliability, and longevity. This attention to detail ensures that the electrical system functions optimally, minimizing the risk of malfunctions and breakdowns.

Automotive technicians who master the art of installing zip ties in confined spaces contribute to the overall quality and dependability of the vehicles they work on. Their expertise helps maintain customer satisfaction and trust in the automotive industry.

Aerospace Industry

Ensuring Safety in Aircraft Wiring

Installing zip ties in tight spaces is vital in the aerospace industry. Aircraft wiring systems are incredibly intricate, with miles of cables running through the fuselage, wings, and other confined areas.

Securing these wires with zip ties is essential for maintaining the integrity of the electrical system and ensuring the safety of passengers and crew. Aerospace engineers and technicians must navigate through tight spaces, such as avionics bays and wire conduits, to properly install zip ties.

Meeting Stringent Aviation Standards

By employing specialized tools and techniques, aerospace professionals can achieve a secure and organized wiring layout that meets the stringent safety standards of the aviation industry. Properly installed zip ties in aircraft minimize the risk of wire damage, reduce the potential for electromagnetic interference, and facilitate easier maintenance and troubleshooting.

The ability to install cable ties in tight areas is a critical skill for aerospace engineers and technicians. Their expertise ensures that aircraft wiring systems are reliable, safe, and compliant with industry regulations.

Electronics and Computer Systems

Optimizing Performance in Compact Devices

In the realm of electronics and computer systems, installing cable ties in tight areas is equally important. Modern electronic devices, such as smartphones, laptops, and gaming consoles, pack a significant amount of technology into compact spaces.

The internal wiring and cable management of these devices require precise and secure installation of cable ties to ensure optimal performance and reliability. Electronics manufacturers and repair technicians must navigate through the tight confines of device housings, carefully routing and securing cables with cable ties.

Enhancing Device Durability and Efficiency

By utilizing the loop method, tweezers, and other specialized tools, electronics professionals can achieve a neat and organized internal layout that maximizes space efficiency and minimizes the risk of component damage. Properly installed cable ties in electronics contribute to improved heat dissipation, reduced signal interference, and enhanced overall device durability.

Mastering the techniques for installing cable ties in tight areas is essential for electronics manufacturers and repair technicians. Their expertise ensures that electronic devices perform optimally, are reliable, and meet the expectations of consumers in terms of quality and longevity.

Construction and Renovation

Ensuring Safety in Building Wiring Systems

Installing cable ties in tight areas is crucial in building construction and renovation. Behind walls, in ceiling cavities, and within conduits, wires and cables need secure organization. This ensures the safety and functionality of electrical and communication systems.

Electricians and contractors navigate these confined spaces to install cable ties. They maintain a tidy and code-compliant wiring infrastructure. Using cable tie installation tools and planning efficient cable routes helps manage wires in tight areas. These techniques ensure professional and reliable results in construction projects.

Facilitating Maintenance and Upgrades

Properly installed cable ties in building systems prevent wires from sagging, reduce the risk of electrical fires, and facilitate future maintenance and upgrades. This attention to detail contributes to the overall safety, reliability, and longevity of the building's electrical and communication networks.

The ability to install cable ties in tight areas is a valuable skill for electricians and contractors. Their expertise ensures that building wiring systems are safe, efficient, and compliant with local building codes and regulations.

Conclusion

Installing cable ties in tight areas may seem daunting, but with the right techniques and tools, it becomes a manageable task. By selecting the appropriate cable ties, utilizing installation tools, and employing methods like the loop technique and strategic cable routing, you can achieve a neat and secure cable management solution even in the most challenging spaces.

Remember to take your time, be patient, and use the right tools for the job. With practice and persistence, installing cable ties in tight areas will become second nature.

Check out Cable Ties Unlimited and choose the best products today!