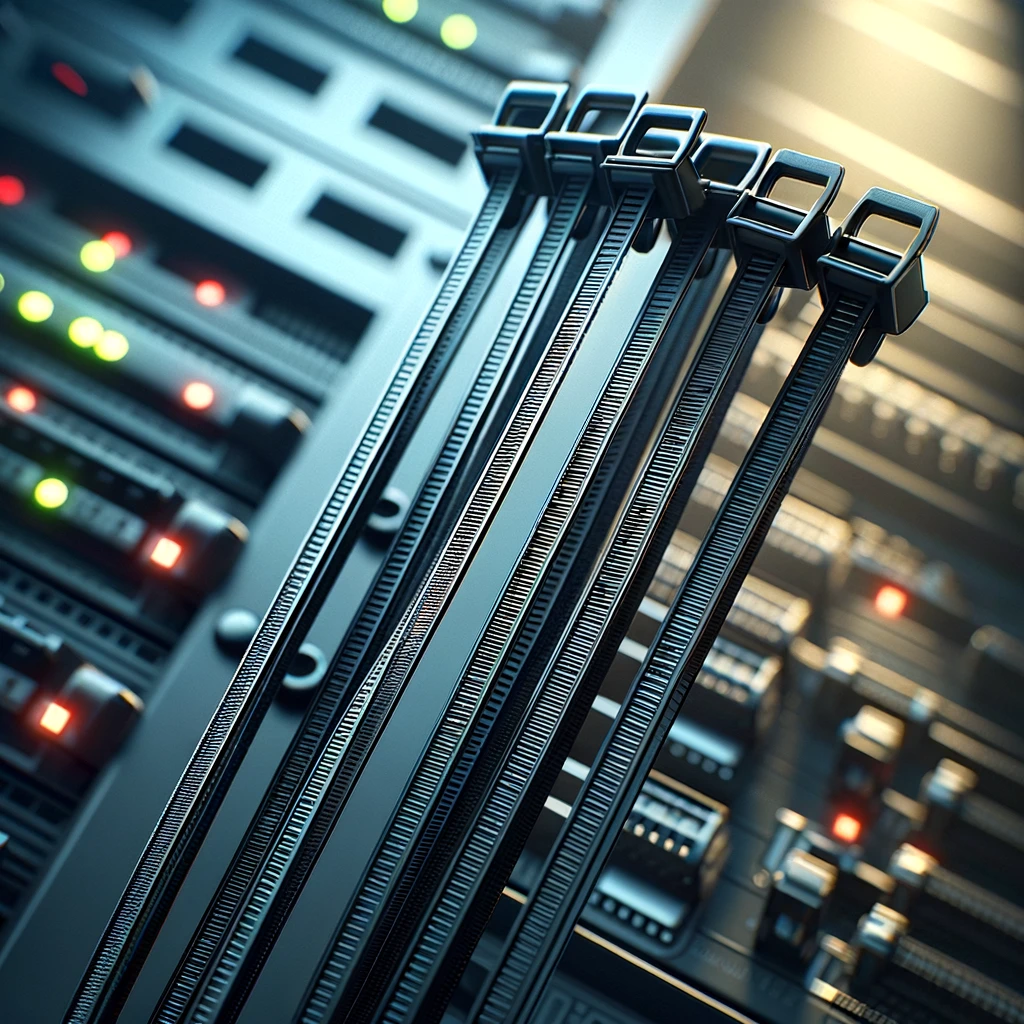

In the world of cable ties, one term that often pops up is the black polyester coating. But what exactly is it and why does it matter? Let's dive in to uncover the ins and outs of this essential component.

The Basics of Black Polyester Coating

Black polyester coating is a protective layer applied to cable ties during manufacturing. It serves several crucial purposes, making it a vital feature for various applications. This coating is primarily designed to enhance the durability and longevity of cable ties, especially in challenging environments.

One of the key benefits of black polyester coating is its resistance to external elements such as moisture, chemicals, and UV radiation. This makes it ideal for outdoor use or in environments where cables are exposed to harsh conditions. Additionally, the coating provides an extra layer of insulation, further safeguarding cables against damage and ensuring optimal performance.

Advantages in Application

When it comes to securing cables, reliability is paramount. Black polyester coating not only fortifies the physical integrity of cable ties but also enhances their gripping power. This ensures a secure hold, preventing slippage or loosening over time. Whether used in industrial settings, automotive applications, or DIY projects, the added strength and resilience of coated cable ties offer peace of mind and confidence in cable management solutions.

Moreover, the sleek black finish of polyester-coated cable ties provides a professional look and helps minimize visibility, creating a neat and organized appearance. This aesthetic appeal, coupled with its functional benefits, makes black polyester coating a preferred choice across various industries.

Exploring Variations and Compatibility

While black polyester coating is a popular option, it's essential to consider specific variations and compatibility factors. Different manufacturers may offer variations in coating thickness or composition, impacting the overall performance and suitability for particular applications. Additionally, compatibility with other components such as cable connectors or mounts should be taken into account to ensure seamless integration and optimal functionality.

Benefits of Black Polyester Coating

Black polyester coating for cable ties offers a plethora of benefits that cater to the diverse needs of users across various industries and applications.

Enhanced Durability and Longevity

One of the primary advantages of black polyester coating is its ability to significantly enhance the durability and longevity of cable ties. The protective layer acts as a shield against external elements such as moisture, chemicals, and UV radiation, which can cause premature deterioration and degradation of standard cable ties. By providing a robust barrier, the coating prolongs the lifespan of cable ties, ensuring reliable performance even in harsh environments.

Improved Grip and Security

Another key benefit of black polyester coating is its ability to enhance the gripping power of cable ties. The added friction provided by the coating ensures a secure hold on cables, minimizing the risk of slippage or loosening over time. This is particularly crucial in applications where cables are subjected to vibrations, movements, or tension. The enhanced grip offered by coated cable ties not only ensures the stability of cable installations but also reduces the need for frequent readjustments or replacements, thus optimizing efficiency and cost-effectiveness.

Aesthetic Appeal and Versatility

In addition to its functional benefits, black polyester coating also enhances the aesthetic appeal of cable ties. The sleek black finish provides a professional look and helps maintain a neat and organized appearance, making it suitable for a wide range of applications, including indoor and outdoor settings. Whether used in industrial facilities, automotive installations, or household projects, coated cable ties offer a versatile solution that combines style with functionality.

Compatibility and Ease of Use

Furthermore, black polyester-coated cable ties are designed to be compatible with various accessories and mounting options, ensuring seamless integration into existing cable management systems. This compatibility enhances the flexibility and versatility of cable tie applications, allowing users to customize and optimize their cable installations according to their specific requirements. Additionally, the ease of use and installation associated with coated cable ties make them a preferred choice for both professional installers and DIY enthusiasts alike.

Tips and Tricks for Using Black Polyester Coated Cable Ties

Maximizing the potential of black polyester coated cable ties requires a combination of knowledge and practical know-how. Here are some tips and tricks to help you make the most out of this versatile cable management solution:

1. Choose the Right Size and Strength

Before purchasing black polyester coated cable ties, consider the size and strength requirements of your application. Opt for ties that are suitable for the diameter and weight of the cables you intend to secure. Additionally, ensure that the tensile strength of the cable ties matches the demands of your specific project to prevent breakage or slippage.

2. Pre-plan and Organize

Before starting your cable management project, take the time to plan and organize your cables effectively. Identify the routes and locations where cables need to be secured and determine the optimal placement of cable ties. This pre-planning will help streamline the installation process and ensure a tidy and organized outcome.

3. Use Tensioning Tools

Invest in quality tensioning tools to ensure proper installation of black polyester coated cable ties. Tensioning tools help achieve the ideal level of tightness, ensuring a secure hold on cables without over-tightening, which can potentially damage the cables or the ties themselves. Proper tensioning is crucial for optimal performance and longevity of cable tie installations.

4. Consider Temperature and Environmental Factors

Take into account the temperature and environmental conditions of your installation environment when selecting black polyester coated cable ties. Ensure that the chosen ties are rated for the expected temperature range and are resistant to moisture, chemicals, and UV radiation if used outdoors or in challenging conditions. This consideration will help maintain the integrity and effectiveness of the cable tie installations over time.

5. Explore Accessories and Mounting Options

Enhance the functionality and versatility of black polyester coated cable ties by exploring compatible accessories and mounting options. Cable tie mounts, clips, and holders provide additional support and organization, allowing you to create custom cable management solutions tailored to your specific needs. Experiment with different accessories to find the most efficient and practical configuration for your application.

6. Inspect and Maintain Regularly

Regularly inspect your black polyester coated cable tie installations to ensure they remain secure and intact. Check for signs of wear, damage, or loosening, and replace any worn or damaged ties promptly to prevent potential issues. By staying proactive with maintenance and inspections, you can prolong the lifespan and effectiveness of your cable management system.

Wrapping Up

In conclusion, black polyester coating plays a crucial role in enhancing the durability, reliability, and aesthetic appeal of cable ties. Its protective properties and compatibility make it a go-to choice for a wide range of applications, offering peace of mind and efficiency in cable management solutions.

Ready to learn more about the latest innovations in cable ties? Explore our latest blog post for expert insights and tips on maximizing the potential of your cable management setup.